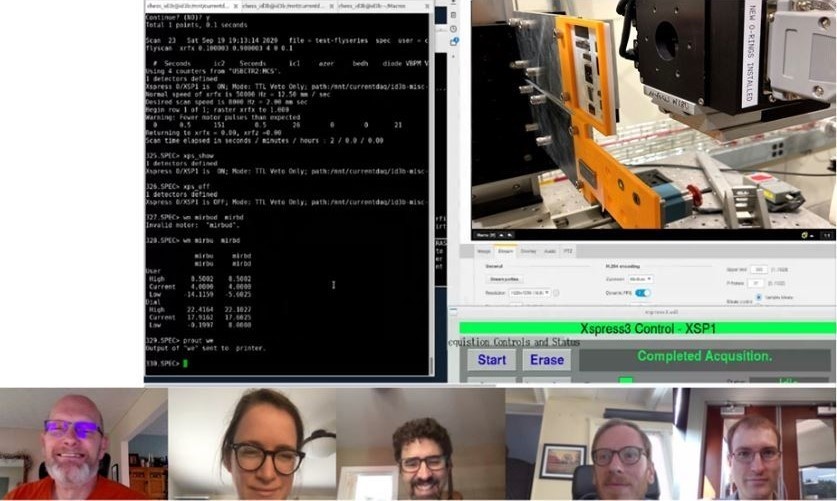

During COVID-19 restrictions, the research team established protocols and routines that allow remote sample manipulation and data acquisition. From left to right: Dr. Hilmar Koerner, Cornell staff scientists Drs. Louisa Smieska and Arthur Woll, and AFRL Materials and Manufacturing research scientists Dr. Edward Trigg and Mr. Andrew Abbott. The black command window with code lines (upper left) shows the UNIX-based software package for instrument control and data collection SPEC. Users can run their own software packages written in the programming language python to position the sample stage and to program automated sample movement. The camera image (AXIS) in upper right shows a close-up of the sample stage in the beamline hutch. While beamline staff mount the samples, everything else is being done remotely from the comfort of either office or home.

| Date Taken: | 03.09.2021 |

| Date Posted: | 03.11.2021 16:33 |

| Photo ID: | 6551939 |

| VIRIN: | 210309-F-GH181-1001 |

| Resolution: | 837x501 |

| Size: | 124.57 KB |

| Location: | WRIGHT-PATTERSON AIR FORCE BASE, OHIO, US |

| Web Views: | 58 |

| Downloads: | 2 |

This work, AFRL partners with Cornell to use micro-beam scanning technology for inspecting composite materials, by Mary Pacinda, identified by DVIDS, must comply with the restrictions shown on https://www.dvidshub.net/about/copyright.