KUWAIT NAVAL, KUWAIT - Soldiers and civilians from the Army Field Support Battalion – Kuwait, headquartered at Camp Arifjan, Watercraft Equipment Site (WES) team, is responsible to maintains accountability for Army Prepositioned Stock Watercraft. Watercraft prepositioned stock, or APS-5, consists of LCUs, LCMs, Barge Derrick Craine, tugs and ferries.

The WES team provides APS-5 watercraft in support of contingency operations and exercises in Southwest Asia. Sgt. 1st Class Robin Blair with ASG-K FSBn said, “We keep these vessels at a high state of readiness to issue to a gaining tactical unit.” Adding, “The HEISCO (Heavy Engineering & Industries Shipbuilding Company) team along with Army and DAC take great pride in the product that comes from this facility.”

The WES team performs Care of Supplies in Storage (along with maintenance of four Army watercraft. The WES team, consisting of CW4 Garnnette Mosley, SFC Robin Blair, Cramer Claxton, Charles Jackson, and Kevin Delaney working jointly with the HEISCO consisting of both US and foreign national contractors, has accomplished many high-impact missions over the last six months.

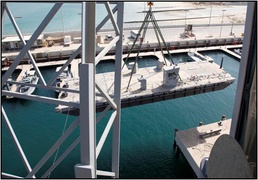

A first for the WES team was the recent activation of the Barge Derrick Crane and two Small Tugs for limited use to dock and undock small watercrafts for annual inspections and maintenance. According to Blair, “The BD crane was essential as it has lift capability. We cannot always use the syncrolift. With the use of the BD crane, we only require use of the rail system.”

The syncrolift is a submersible rail and pier system. It can be lowered by a system of pulleys and cable into the water. The vessels can then be chocked by divers on mounts that are on a rail system and raised back up.

Being able to utilize the BD crane is only half the process. Getting the vessels into position is the other half. “Small tugs are used to position the BD for use. The small tugs position vessels in port that are being ‘put in’ and retrieve vessels from their berth to be ‘brought out’ or dry docked” said Blair.

This allowed the team to undock, two Landing Craft Mechanized (LCM) Mod 1 vessels weighing 60 tons each, one LCM Mod 2 weighing 85 tons and one Causeway Ferry (CF) weighing 90 tons. Docked,were two LCMs Mod 1, one LCM Mod 2, and one Warping Tug (WT) weighing 94.5 tons..

The amount of man-hours and man-power to complete this mission was well above and beyond the stan-dardBut throughout the entire process safety and communication were always a priority in getting the vessel from the crane to the synchrolift. “Safety is the biggest aspect. Think of 95 tons hanging over your head, everyone has to be alert and on point,” said Blair.

This process is time consuming, comprising of eight lifts over two days, but essential to keep vessels on the water supporting logistics missions said Blair, adding, “It is the maintenance cycle that we are concerned about. These watercraft must be rotated in and out of the wet and dry storage to exercise all the pumps, motors, etc onboard.”

Blair concludes with, “The HEISCO team along with the Army and DAC take great pride in the product that comes from this facility.”