Delivering therapeutics can be tricky under the best circumstances – needles need to be administered precisely either subcutaneously, intramuscularly or intravenously which takes valuable time. Producing easy access therapeutics requires careful planning and foresight, and for a warfighter on the battlefield, time may be limited. The Defense Threat Reduction Agency’s Chemical and Biological Technologies Department is funding research to revolutionize the production of microneedle patches, which will allow warfighters to quickly and effectively self-administer potentially life-saving therapeutics.

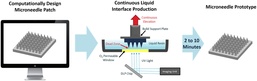

Scientists from the University of North Carolina at Chapel Hill (UNC) have developed a new method for producing microneedle patches, known as Continuous Liquid Interface Production (CLIP). CLIP overcomes several obstacles of traditional additive manufacturing, allowing scientists to create various microneedles patch designs in minutes.

Microneedles provide arrays of sharp, sub-millimeter-sized needles that enhance transdermal drug delivery by perforating the epidermis, enabling direct therapeutic delivery. Unlike hypodermic needles, microneedles avoid nerve endings buried deep within the skin, providing pain-free drug delivery.

CLIP can rapidly prototype microneedles of a wide variety of sizes, shapes and compositions with modular control over each factor. The rapid and tunable nature of the CLIP technique will enable the high throughput, systematic investigation of parameters associated with microneedle design and accelerate the technology into clinical settings.

Using ex vivo murine skin models, researchers assessed the ability of CLIP-manufactured microneedles to puncture the skin and deliver therapeutics. Microneedles of four different compositions were applied by pressing firmly on the back of the patches for 10 seconds. When the patches were removed, a green tissue marking dye was applied to mark skin penetration. All four microneedle compositions successfully breached murine skin.

The CLIP process enables cargo to be localized to the microneedle tip, maximizing the efficiency of delivery to the skin. This can be used to produce microneedles from derivatives of widely used biocompatible polymers capable of controlling the release of cargo into the body.

Microneedles deliver a range of therapeutics that are difficult to administer orally, such as proteins, nucleic acids and large, hydrophobic molecules. Although numerous materials have been utilized, microneedles fabricated from biocompatible materials are considered the gold standard for patient safety as they avoid immunological risks associated with accidental microneedle fragmentation within the skin.

CLIP demonstrates the most versatile microneedle prototyping to date with the ability to rapidly generate microneedles of various sizes, shapes, aspect ratios, spacing and compositions, suitable for a variety of therapeutics. This revolutionary capability will allow warfighters to deliver therapeutics on-demand through a printed patch within seconds of exposure. Not only will this new technology save priceless warfighter lives, it will also provide enhanced readiness and enable warfighters to operate successfully in any environment.

POC: Dale Taylor; dale.e.taylor4.civ@mail.mil