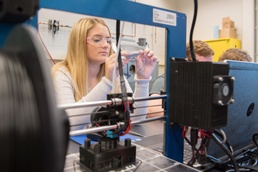

ABERDEEN PROVING GROUND, Md. (Aug. 3, 2017) – Surrounded by the buzz of industrial 3-D printers, a group of six high school students and three educators are spending a couple of weeks with the U.S. Army Research Laboratory learning about additive manufacturing and computer-aided design concepts.

As part of a federal program from the Defense Threat Reduction Agency, the Joint Science and Technology Institute is a fully-funded, residential science, technology, engineering and mathematics research program for current high school students in the United States and Department of Defense schools around the world, as well as teachers.

“We’re involved in a program with JSTI to do some research or learn some things so we can take it back to our schools and share with our students what’s happening out in the real world,” said Raye Pedigo, a high school physics and calculus teacher in Jefferson County, Tennessee.

The students and teachers are refining their projects on computer-aided design, or CAD software and sending their finished concepts to 3-D printers.

“We’re teaching them about 3-D printing, how to run the machines, how to use the CAD software, and that’s usually the hardest thing for the students to pick up,” said Jolie Frketic, a mentor for the program and an ARL intern. “They come in for a couple of weeks and they’re able to see what we do here as well as learn from us.”

Army researchers use additive manufacturing to discover new possibilities in materials science with an eye on innovating technology solutions for future Soldiers.

“By introducing additive manufacturing to students, we are providing them with a way to express their artistic and engineering thoughts in three dimensions, both virtually --through design-- and physically --though 3-D printing,” said Larry (LJ) Holmes, a mentor and researcher at the laboratory. “Students are able to create variations of part designs, rapidly evaluate their performance and re-design based on performance analysis. For relatively small objects, this can be done in a single day.”

The manufacturing industrial base is still in the early stages of acceptance of additive manufacturing technologies for mass productions, Holmes said, but it uses the technology for engineering prototypes, “just like these students are doing here at ARL,” he said.

Holmes said by providing insight and education through STEM activities like JSTI it “ensures that the next generation of scientists and engineers are not simply able to use these types of technologies, but are in a position to push AM capabilities beyond the current state-of-the-art.”

“There are so many experts and amazing equipment here,” said Blaise Vanderploeg, an American student at the Frankfurt International School in Germany. “I’m currently interested in material science, but I actually love learning everything, so 3-D printing is definitely something. I’m really happy I did this.”

The kind of additive manufacturing the group used during their program is a process of adding material layer-by-layer through an extruder. Current printers are not without challenges.

“Right now there are still a lot of limitations, like for example, some of the printers are not printing the resolution we want or they’re messing up in the middle of a job, so I think those things will improve and then it will be easier to print, faster to print and more people will be able to print,” said Alexa Hui, a student at St. Thomas Aquinas High School in Fort Lauderdale, Florida.

With advances in technology, additive manufacturing may provide a new way to make complex parts that couldn’t be produced any other way.

“The potential in 3-D printing is really endless,” said Conrad Wyrick, a student at Fort Walton Beach High School in Fort Walton Beach, Florida. “There are so many things that can be done with it and there are so many more materials that people are working on to print in medicine and technology in general.”

The students are optimistic about the pace of innovation.

“Everything around us is based on STEM, Wyrick said. “The world today and the world tomorrow…it’s going to be based around technology…science…and I feel that it’s always great to strive. Striving for more is the greatest thing.”

The students are quick studies, Frketic said.

“They pick up technology even faster than I do,” she said. “It’s funny teaching them. I’ll be like, ‘I’m not sure how to do that,’ and two minutes later they’ll have it figured out. I think they grew up with technology even more than I did.”

The Joint Science and Technology Institute offers a wide variety of research projects across many scientific disciplines. Across the nation this year, the program included 59 high school students, 29 middle school students and 10 teachers. Find out more at the JSTI homepage.

“There are a lot of excellent people here and the mentors are very good,” said Dr. Haridas Chandran, a teacher at Belfry High School in Belfry, Kentucky. “They are giving away their time to give us a good experience.”

“I definitely would recommend getting involved in the programs because, you don’t get to pick which project you work on, I didn’t get to pick this project, so it broadens your horizons and introduces you to something you might not have been interested in,” Hui said. “You get to meet so many people and it expands your world view.”

-----

The U.S. Army Research Laboratory, currently celebrating 25 years of excellence in Army science and technology, is part of the U.S. Army Research, Development and Engineering Command, which has the mission to provide innovative research, development and engineering to produce capabilities that provide decisive overmatch to the Army against the complexities of the current and future operating environments in support of the joint warfighter and the nation. RDECOM is a major subordinate command of the U.S. Army Materiel Command.